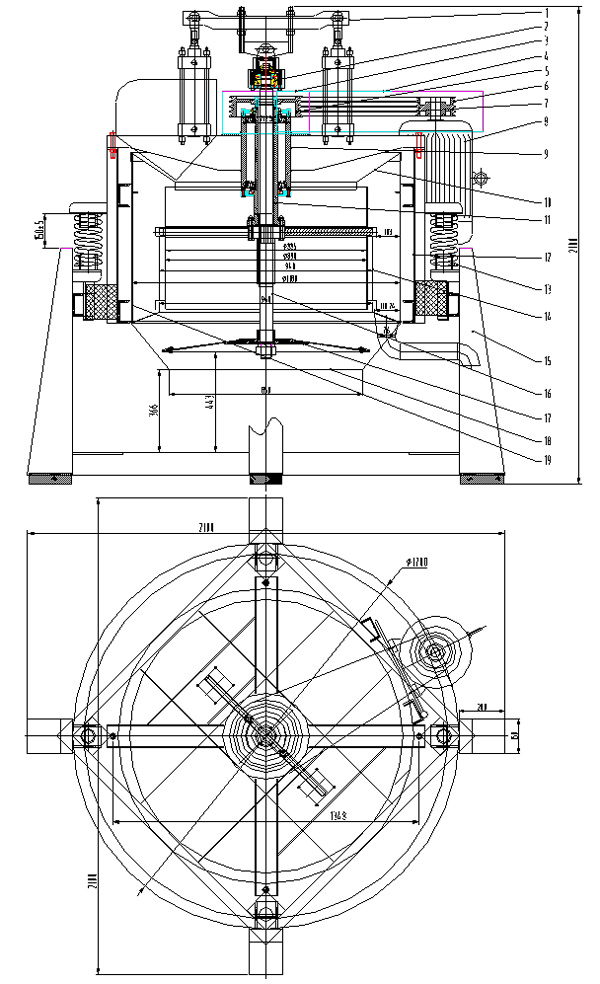

LG-900 vertical automatic centrifugal machine

Description

Lg-900 vertical automatic centrifugal machine this model adopts quadruped suspension structure, equipped with spring, rubber pad has better vibration protection effect. The upper part of the shaft is equipped with a starting wheel structure, PLC frequency conversion speed regulation, when starting, so that the internal drying sieve gradually accelerated, do not make the motor overload. The internal swing - dry screen is balanced and safe. High dehydration rate, large capacity, the internal swing drying sieve is made of high quality stainless steel, durable. High dehydration rate and large capacity. Used in vegetables, food, medicine, environmental protection and other industries ideal dehydration equipment.

Structure Characteristics

The machine is based on the technical parameters of vegetable processing materials, the application of frequency conversion technology and electrical sensing technology to achieve the working time, working speed and start, stop control; It has the characteristics of safe and reliable operation, simple operation, low noise, high production and so on.

The drive control system is composed of high quality frequency conversion governor and electrical sensor and other control components. The operation time and speed are easy to adjust and the transmission is reliable. The operation speed should be adjusted within the allowed range of the machine, and the highest speed is 1400rpm.

1. The support of the centrifugal pumping machine is 4-foot support suspension structure, and the 4-foot support pad is high quality thick rubber plate. The swing bucket support is connected with the bottom base by 4 high quality large diameter cylindrical spiral compression springs and 4 high quality thick rubber plates, which can avoid the foot vibration caused by the load imbalance in the rotating screen during operation.

2. The shell and the contact with the material are made of stainless steel.

3. The spindle is made of high quality steel after heat treatment and finishing.

4. The drive part adopts triangle belt drive, the frequency conversion motor directly drives the centrifugal starting wheel, PLC control can make the machine slowly start, gradually reach the design speed, to ensure the balance of the machine operation.

5. Feeding, discharging through the lower end of the rotating shaft and other material plate up and down action to achieve.

6. The rotation shaft lift using φ125 large diameter cylinder pneumatic control, discharging there are 2 air nozzle controlled by solenoid valve inclined blowing and drying screen wall, blowing clean.

7. Machine rotation, lifting, pneumatic blowing and other actions are controlled by the electric control box PLC man.

Instructions for operation of industrial centrifugal machine

1. Feeding: before the process hoist, timing feeding, at this time the main shaft of the machine rotating at low speed (about 300r/min), the material plate closed, the material evenly distributed on the material plate. The material is evenly and flatly distributed into the sieve, paying attention to balance, uniformity and no overload.

2. After about 30-90 seconds of feeding, the speed of frequency conversion motor is gradually increased to about 1200r/min from low speed rotation. When the machine reaches normal operation, the outlet pipe begins to give water in large quantities.

3. The spindle high-speed rotation about 90 seconds, basically no water outflow of the outlet pipe, spindle rotation from high speed to low speed rotation (about 300r/min), cylinder action and other material disk down discharge, solenoid valve action air nozzle oblique blow and dry screen wall, air nozzle blowing clean wall material, the process takes about 30 seconds.

4. The spindle from low speed rotation speed to medium speed (about 600r/min), throw out the remaining material on the material plate, the process takes about 20 seconds.

5. The end of drying, discharging until the hoist to the next process. The total process takes about 4 minutes and the cycle is automatic.

6. The time, speed and other parameters of each action step above can be adjusted and set by PLC man-machine interface according to the production process.