Magnetic vibration screening

Product Introduction

The unit is a new product that imitates the equipment imported in 2005. It is composed of hoist, vibrating screen air separator and dust collector.

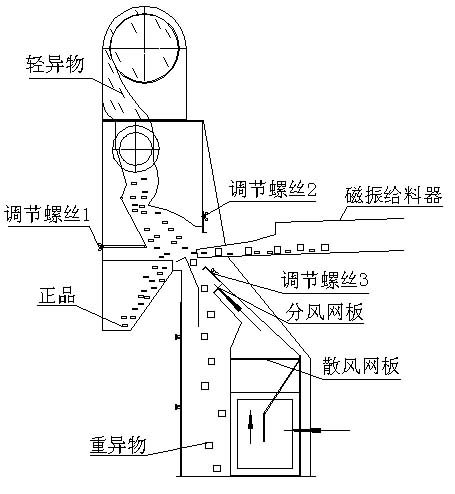

The material is sent to the inlet end of the screen frame with electromagnetic vibration device by the hoist. Sieve frame under the action of electromagnetic force, for periodic reciprocating vibration. The material in the sieve is constantly thrown up and leaps forward. When the material moves forward evenly and continuously, it is automatically graded by 45° organic glass diagonal screen of different specifications, and the small powder particles and large particles are collected into the recycling box of different levels. The rest of the material into the air chamber, through the action of floating air flow, mixed in the material of heavy objects fall into the heavy recycling box, light objects are brought to the cyclone dust collector, into the waste recycling box. Genuine products are sent from the front to the next process.

The unit automatic feeding, continuous operation, stepless air regulation, high separation accuracy. It can be used with X-ray machine, metal testing machine to form a new product packaging line. It is the ideal packaging equipment for vegetable processing and food industry.

Technical Parameters

| Dimension (mm) |

Hoist | Magnetic vibration wind selector | Cyclone | |||

| 3500*1300*1900 | Motor (v) |

Conveyor (mm) |

Sieve screen | Power (kw) |

Power (kw) |

Wind closing power (w) |

| 350 | 380*2 | φ3.5-φ20 | 0.45 | 1.1 | 60 | |

| Capacity (kg/h) | ||||||

| Dried spring onion | Sweetened product | |||||

| 200-400 | 800-1000 | |||||

Precautions for Use

The machine has been debugged before leaving the factory, in the processing of different products, the necessary debugging, the steps are as follows:

When empty, if abnormal jitter is found in the electromagnetic vibration part, you can fine-tune the amplitude adjustment knob on the power distribution cabinet and observe the amplitude change at the same time. The ammeter indicates that the amplitude should be in the rated range (1-2.3a).

Different materials need to change the position of screen box discharge end. When changing the horizontal position, loosen the 4 bolts of the electromagnetic vibration base below the screen frame, the base can be moved forward or backward; When changing the height position, tighten or loosen the bolts on the four corners of the frame properly.

The separation effect of genuine, light and heavy foreign bodies is related to the adjustment of no. 1, 2 and 3 adjusting screws as shown in the left picture and the adjustment of the inverter controlling the fan, which needs to be repeatedly adjusted and recorded.

Ⅲ、The installation

1. The centrifuge should be fixed on the overall concrete foundation, and can be poured according to the foundation size drawing (see the right picture and the table below);

2. Foundation should be embedded anchor bolts, foundation shape should be greater than the triangle chassis size of 100 mm, after the concrete dry, can be lifted into place, and horizontal correction;

3. The electric motor should be installed by electrician according to the electrical schematic diagram, and at the same time do a good job of waterproof and wet protection, explosion-proof motor should be equipped, the user should put forward the selection notice.

|

|

D1 |

D2 |

A |

B |

|

LG-800 |

1216 |

1650 |

100 |

140 |

|

LG-1000 |

1416 |

1820 |

100 |

160 |

|

LG-1200 |

1620 |

2050 |

100 |

180 |

Ⅳ、Maintenance and maintenance

1. The centrifuge must be operated by a special person, do not increase the loading limit at will, pay attention to check whether the rotation direction is consistent with the operation;

2. It is not allowed to increase the speed of the centrifuge at will. After 6 months of use, it is necessary to carry out a comprehensive inspection, clean the drum parts and bearings, and add lubricating oil;

3. Regularly check whether the solid parts of the centrifuge are loose;

4. In 6 months (since the date of purchase) product quality implementation of three guarantees, such as improper operation caused or caused damage to the machine by the user's own responsibility.