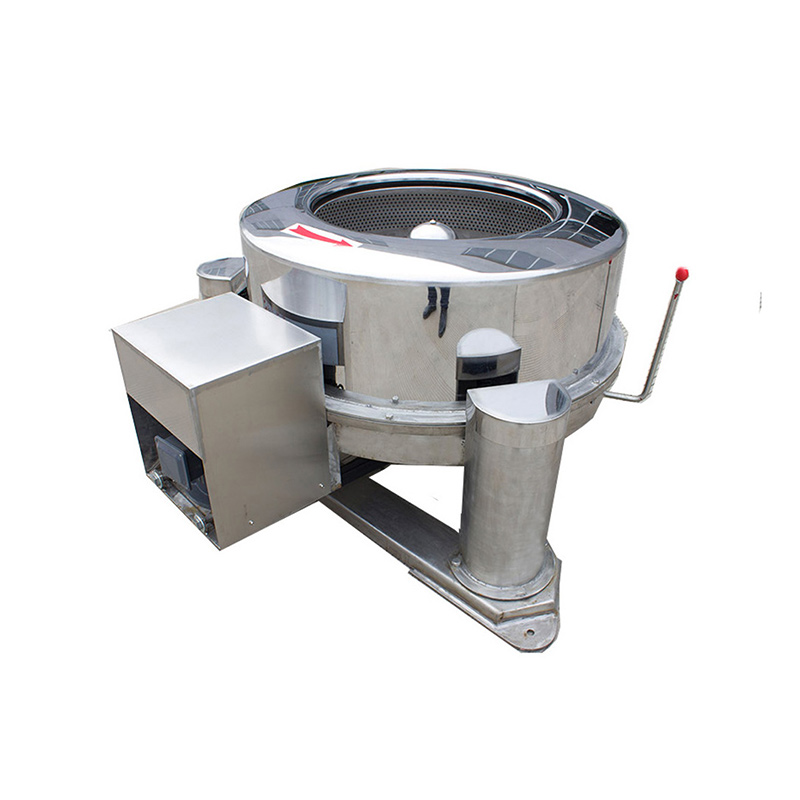

Tripod centrifugal dehydrator machine

Description

Centrifugal ejector is a general mechanical equipment for clearance operation, which is composed of shell, drum, chassis, hanger rod, damping spring, batching box transmission parts, clutch and brake device parts. When the machine runs normally, the material is evenly distributed on the inner wall of the drum under the action of centrifugal force, and the liquid attached to the material is thrown to the inner wall of the shell through the hole on the wall of the drum, and discharged from the outlet after collection, while the solid material stays in the drum to complete the separation process of centrifugal filtration. When the separation requirements are met, the motor is turned off, the brake stops, and the material is taken out from the drum manually.

It is suitable for dewatering in vegetable processing and can effectively remove moisture on the surface of vegetable processing. The drum and shell of this product are made of stainless steel, which meet the requirements of food hygiene.

Ⅰ、Main technical specifications

|

Model |

Power(kw) |

Drum diameter(mm) |

Maximum carrying weight(kg) |

Drum speed(r/min) |

Dimensions(mm) |

Weight(kg) |

|

LG-φ800 |

4 |

φ800 |

80 |

910 |

φ1400×820 |

500 |

|

LG-φ1000 |

5.5 |

φ1000 |

110 |

900 |

φ1720×840 |

1400 |

|

LG-φ1200 |

7.5 |

φ1200 |

150 |

740 |

φ1920×935 |

1600 |

Ⅱ、Operation method

1. Before power operation, the following parts should be checked first.

(1) Loosen the brake handle and turn the drum by hand to see whether there is a dead or stuck phenomenon.

(2) Brake handle, brake is flexible and reliable.

(3) Whether the connecting bolts of the motor part are fastened, adjust the triangle belt to an appropriate degree of tightness.

(4) Check whether the anchor bolts are loose.

2. Check that the above is normal before running with power on. The rotation direction of the drum must conform to the direction indicator (clockwise when viewed from above), and it is strictly forbidden to run in the opposite direction.

3. Put the material into the drum as evenly as possible, and the weight of the material shall not exceed the rated maximum loading limit.

4. At the end of dehydration, the power supply should be cut off first, and then the brake handle should be operated to brake slowly, generally within 30 seconds. Do not brake sharply to avoid damage to parts. Do not touch the drum with your hands when the drum is not completely stopped.

Ⅲ、The installation

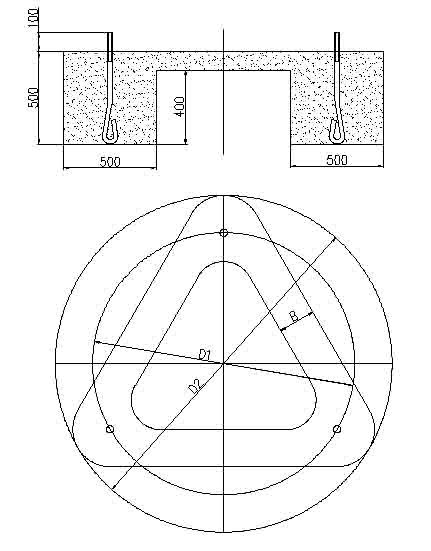

1. The centrifuge should be fixed on the overall concrete foundation, and can be poured according to the foundation size drawing (see the right picture and the table below);

2. Foundation should be embedded anchor bolts, foundation shape should be greater than the triangle chassis size of 100 mm, after the concrete dry, can be lifted into place, and horizontal correction;

3. The electric motor should be installed by electrician according to the electrical schematic diagram, and at the same time do a good job of waterproof and wet protection, explosion-proof motor should be equipped, the user should put forward the selection notice.

|

|

D1 |

D2 |

A |

B |

|

LG-800 |

1216 |

1650 |

100 |

140 |

|

LG-1000 |

1416 |

1820 |

100 |

160 |

|

LG-1200 |

1620 |

2050 |

100 |

180 |

Ⅳ、Maintenance and maintenance

1. The centrifuge must be operated by a special person, do not increase the loading limit at will, pay attention to check whether the rotation direction is consistent with the operation;

2. It is not allowed to increase the speed of the centrifuge at will. After 6 months of use, it is necessary to carry out a comprehensive inspection, clean the drum parts and bearings, and add lubricating oil;

3. Regularly check whether the solid parts of the centrifuge are loose;

4. In 6 months (since the date of purchase) product quality implementation of three guarantees, such as improper operation caused or caused damage to the machine by the user's own responsibility.