Low MOQ for Peel Remover Machine - LG-700 Powder Mixing Machine – Ligong

Low MOQ for Peel Remover Machine - LG-700 Powder Mixing Machine – Ligong Detail:

Ⅰ、Equipment introduction

Ⅱ、Main parameters of equipment

|

Item |

Unit |

Parameter |

Remarks |

| The barrel volume |

L |

780 | |

| power |

Kw |

5.5 | |

| voltage |

V |

380 | Can be customized |

| frequency |

Hz |

50 | |

| Mixing efficiency |

% |

95-99 | |

| capacity |

Kg/h |

2000-4000 | |

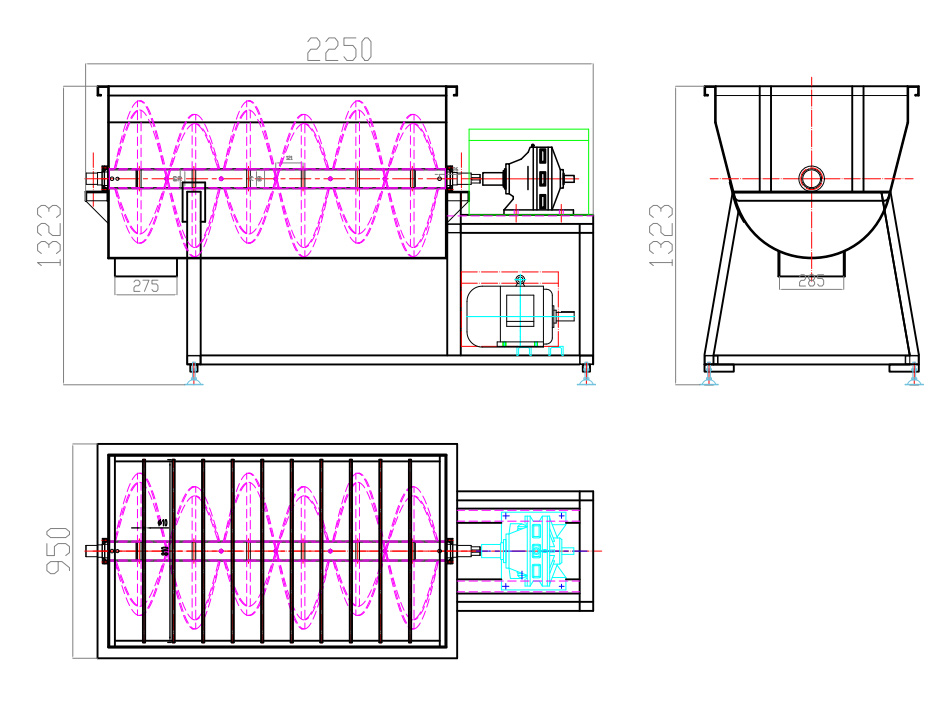

| Effective size of mixing drum |

mm |

1500×850×760 | |

| Inlet height |

mm |

1330 | |

| Inlet dimension |

mm |

1500×850 | |

| Outlet height |

mm |

445 | |

| Discharge port size |

mm |

275×200(Can be customized electric, air butterfly valve) | Can be customized |

| Overall dimensions |

mm |

2230×950×1130 | |

| weight |

Kg |

370 |

(Equipment assembly outline drawing)

Ⅲ、Equipment installation

Ⅳ、Steps of operation

1. The operator should be familiar with the performance of the whole equipment and understand the function and operation method of each component of the unit.

2. before starting the machine, we must carefully check the connection parts of mechanical and electrical equipment, bolts and other should not be loose, whether there is a stuck phenomenon, do not fall into foreign bodies, all normal before starting.

3. the machine can feed after normal operation, the main material and premix into the body at the same time, evenly feed, not a large amount of sudden pouring, material surface to the main shaft above, start timing, positive turn 1 minute reverse 1 minute, and then positive turn 1 minute reverse 1 minute, 4-6 minutes after the start of unloading.

Ⅴ、Matters needing attention

1. according to different kinds of materials, should be added less frequently, mixing time determines the uniformity, material shall not be mixed with sundry hard objects, wire, otherwise affect the life of the machine.

2. before the production starts, first no-load operation test, check the operation of the mixing shaft, check whether the transmission part is normal.

3. do not place any irrelevant items on the machine, so as not to start the accident.

4. Once abnormal phenomenon is found during operation, the power supply should be cut off immediately (emergency stop button) and stop for inspection.

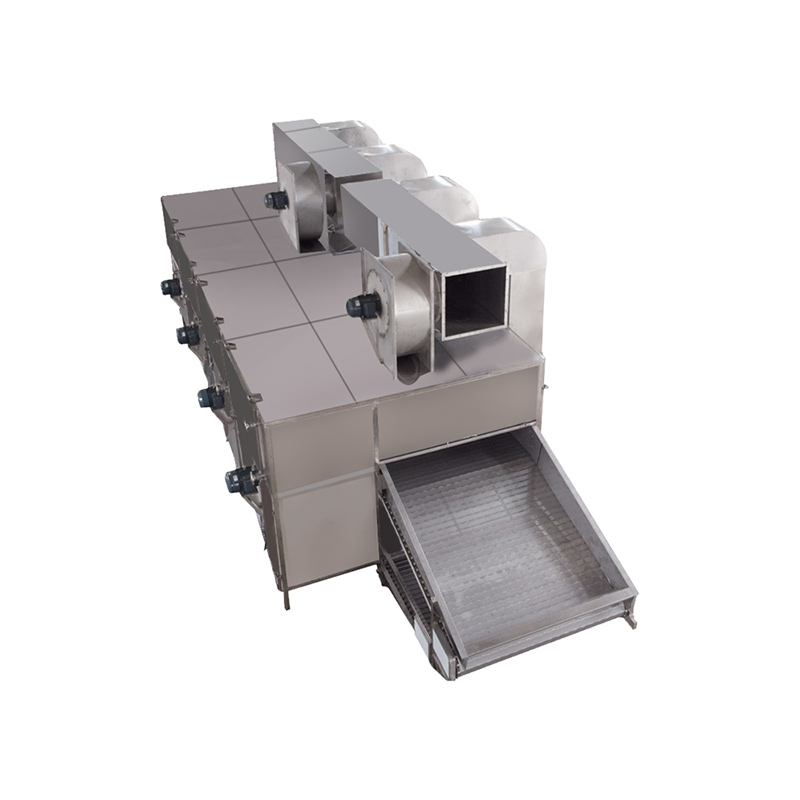

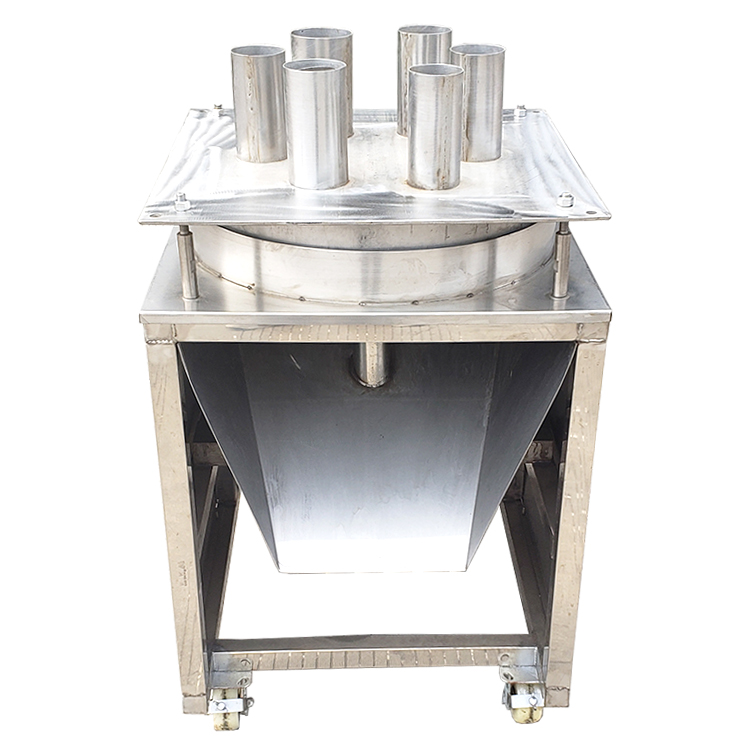

Product detail pictures:

Related Product Guide:

In an effort to provide you advantage and enlarge our business enterprise, we even have inspectors in QC Staff and assure you our greatest provider and item for Low MOQ for Peel Remover Machine - LG-700 Powder Mixing Machine – Ligong, The product will supply to all over the world, such as: South Africa, Irish, Lyon, We believe that good business relationships will lead to mutual benefits and improvement for both parties. We have established long-term and successful cooperative relationships with many customers through their confidence in our customized services and integrity in doing business. We also enjoy a high reputation through our good performance. Better performance will be expected as our principle of integrity. Devotion and Steadiness will remain as ever.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!