Manufacturing Companies for Salad Cutter Electric - LG-750 Multi-functional Vegetables Cutting Machine – Ligong

Manufacturing Companies for Salad Cutter Electric - LG-750 Multi-functional Vegetables Cutting Machine – Ligong Detail:

Technical parameters and its description

The use of notes

(1) The machine is equipped with a safety device, the motor is running normally, and the door is open. Running away from the high speed of the blade.

(2) Blade grinding should be sharp, knife and knife edge clearance for the installation and adjustment of 0.5 ~ 2.0mm.

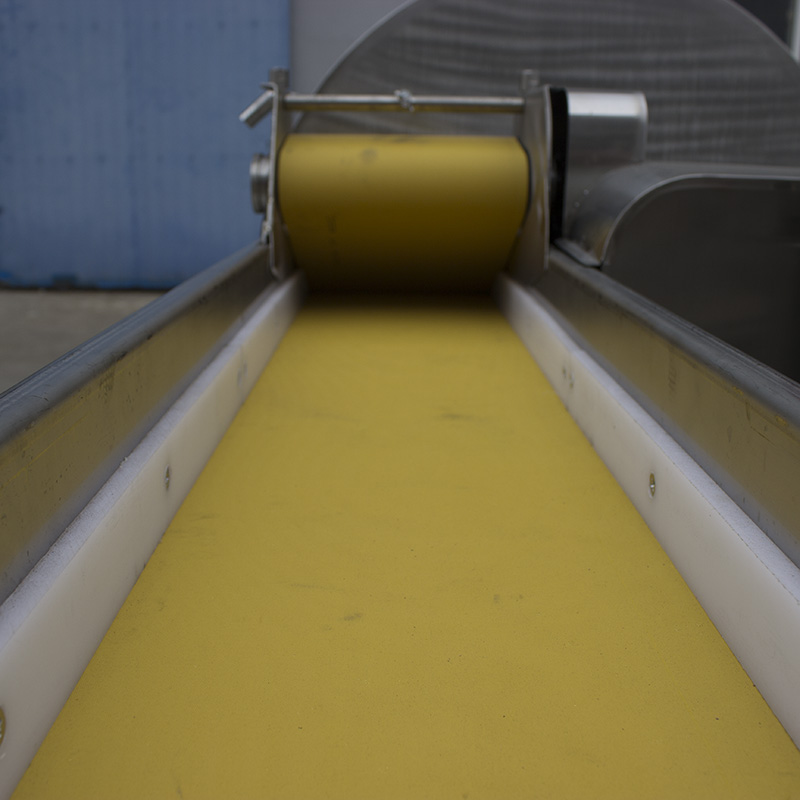

(3) Up and down the conveyor belt position must be adjusted in the middle of the conveyor, the tightness of the spring screw is appropriate.

(4) Feeding layer should be smooth and neat, highly consistent and continuous feeding staggered can achieve good grain shape, neat incision. The length of the agreement.

(5) Cutting material is adjusted, the power switch is cut off, and the speed regulation is not required to return to zero.

(6) Often note that the material can not be stuck into the conveyor belt inside and the surface of the roller, once the product will affect the particle shape, or cut off the conveyor belt. Once the card enters, immediately stop cleaning, usually 4 hours to clean up.

(7) Machine operation must be balanced, such as the discovery of vibration should be checked. Otherwise, will be a bad speed meter or unsafe accident.

1) pole cutting, plate:

A, factory equipped with a good arc knife assembly (see figure). Because of cutting tool wear and vibration, can increase or decrease in gasket.

B, second pieces of arc knife in the position of weight, the first cut, second knife balance. Before and after the two knife should be used to exchange, in order to prevent one of the wear out of balance.

2) double knife cut section, piece (see figure).

(8) Cut shape, wire cutter shape with custom assembly. Cutter

The assembly is made of aluminum alloy, stainless steel cutter knife, knife, knife, high grain aluminum alloy pad, plastic pad, mask. The cutter cut 25mm above the bulk material, the factory shall be installed with a good balance of mask.

Cut size: width = knife grain spacing, length = length (by feeding conveyor speed set).

Knife grains play at the end of the note is greater than or equal to send trough at the end of the line, the rest of the grain cutter spacing according to the requirements of the specification are uniformly distributed and arranged, otherwise bad products increased.

Electromagnetic speed motor wiring and operation method

(1) Line: for three-phase four wire, three red (green) line is connected with the three-phase power supply, single yellow zero line.

(2) Start: press the green start button, the knife disc motor operation, according to the controller of the toggle switch (break through), regulating knob angle, that is, to change the cutting length.

(3) Stop: in the opposite direction adjustment knob reset to zero, press the toggle switch controller (on-off), press the red button to stop.

Inverter control motor wiring and operation method

(1) Line: three-phase three wire system, there is a green yellow double color line exposed in the control box, this line is to protect the ground, the machine is installed, it must be ground, otherwise the operator will feel numb.

(2) Start: according to the green start button to switch to the cutter head motor running to open the inverter switch to adjust the inverter knob, that is to change the cutting length.

(3) Stop: press the red stop button.

Bearing, oil seal

(1) Main shaft bearing: 2073 sets; oil seal: 3558122

(2) On the conveyor belt double sealed bearing: 1802045 sets

(3) Reduction gear box bearing: 2054 sets, 2062 sets; the oil seal 2542104, 3045102; the bridge shaft outer spherical bearing: P205 1 set

Product detail pictures:

Related Product Guide:

We support our purchasers with ideal high-quality merchandise and significant level company. Becoming the specialist manufacturer in this sector, we now have received loaded practical encounter in producing and managing for Manufacturing Companies for Salad Cutter Electric - LG-750 Multi-functional Vegetables Cutting Machine – Ligong, The product will supply to all over the world, such as: Pretoria, Victoria, Tanzania, We take measure at any expense to achieve essentially the most up-to-date equipment and approaches. The packing of nominated brand is our a further distinguishing feature. The items to assure years of trouble-free service has attracted a great deal customers. The solutions are obtainable in improved designs and richer assortment, they're created scientifically of purely raw supplies. It readily available in a variety of designs and specifications for your selection. The most recent kinds are a great deal better than the preceding one particular and they are quite popular with lots of prospects.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!