Short Lead Time for Fruit Drying Machine - Three Layer Belt Dryer – Ligong

Short Lead Time for Fruit Drying Machine - Three Layer Belt Dryer – Ligong Detail:

I. Equipment Introduction

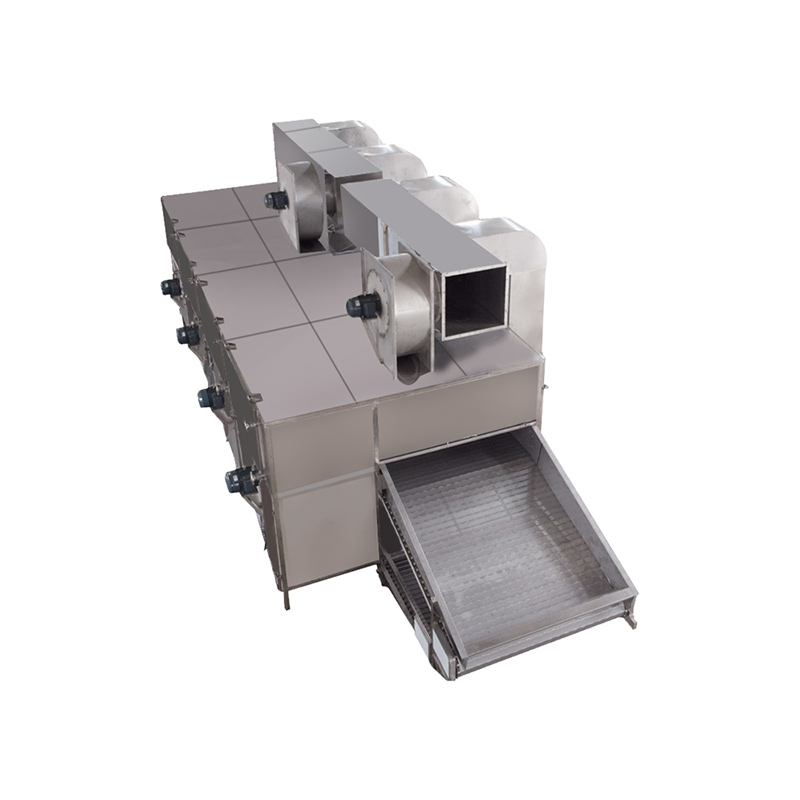

Multi-layer dryer, also known as multi-layer turnover dryer, is a special equipment for dewatering and drying fresh plants or seasonal vegetables, fruits and medicinal materials.

Multi-layer dryer adopts multi-layer mesh belt conveyor belt, because of material shredding, prevent material falling, the use of small mesh belt, good air permeability, high thermal conductivity.

Conventional steam supply using coal boiler gas supply, due to environmental protection reasons, natural gas and liquefied gas become the main choice of energy dryer, natural gas and liquefied gas need conversion furnace, which increases the production cost, but the production cost of natural gas and liquefied gas is low.

The pure hot air produced by hot blast stove, the temperature of hot air is 50℃-160℃ controllable, and the drying and dehydration methods of heating and ventilation are carried out at the same time. The reasonable adjustment of hot air ventilation volume is strengthened. The multi-layer drying layer is cycled and rotated, layer by layer drying, making full use of hot air, drying and dehydration is rapid and efficient.

The air volume of the blower is driven to ensure the timely removal of water vapor and the humidity balance in the box.

Vegetable and fruit dryer is designed automatic drying equipment according to the material drying process requirements change, variety, temperature and humidity sensitive characteristics. The equipment is composed of high efficiency and energy saving hot blast stove, automatic circulation drying chamber and automatic feeding and discharging device. The contact parts are made of stainless steel.

The machine has the advantages of simple structure, convenient operation, labor-saving, environmental protection, automatic temperature control, mechanical moisture discharge and automatic material spreading.

Characteristics of multi-layer dryer:

1. Mass continuous production can be carried out, and to a large extent to protect the nutritional ingredients and color of the product.

2. According to the characteristics of vegetables and fruits, adopt different technological processes and add necessary auxiliary equipment.

3. Large drying output, fast drying speed, high dry efficiency, fuel saving, high thermal efficiency, good dry color.

Multi-layer dryer is widely used in dehydrated vegetables, tea, dried fruit, seasoning, medicine, food and other industries.

Ⅱ. Equipment Installation

Ⅲ. Operation Steps

1. The operator should be familiar with the performance of the whole equipment and understand the function and operation method of each component of the unit.

2. Before starting the machine, we must carefully check the connection parts of mechanical and electrical equipment, bolts and so on should not be loose, whether there is a jam phenomenon, no abnormal sound, all normal before starting.

3. Ensure that the doors on both sides are closed tightly and the maintenance Windows are closed.

4. The machine can be fed after normal operation, uniform feeding, not steep and large amount of material.

5. The top of the dryer, depending on the situation of the customer for exhaust exhaust hood.

Ⅳ. Notes

1. According to different types of materials, ensure uniform feeding.

2. Before production start, first no-load operation test, check the vibration plate operation, check whether the transmission part is normal.

3. Do not place any irrelevant items outside the vibration plate, so as not to boot accidents.

4. Once abnormal phenomenon is found during operation, the power supply should be cut off immediately (emergency stop button) and stop for inspection.

5. If startup is abnormal, check whether the fasteners are loose; Check the operation of each reduction motor; Check sprocket chain running smoothly.

Ⅴ. Production Line Configuration

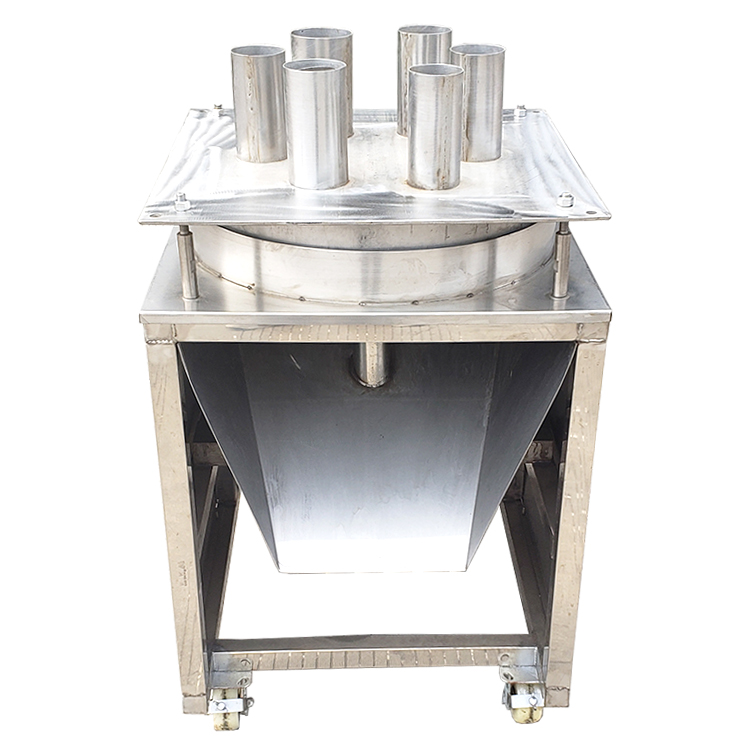

Multi-layer dryer is normally configured to the automatic production line, the first process is the material cutting or blanching after cooling and draining, the last process is the material magnetic separation, air selection, color selection, packaging and other post-processing.

Product detail pictures:

Related Product Guide:

With dependable high quality approach, great reputation and excellent customer support, the series of products and solutions produced by our firm are exported to lots of countries and regions for Short Lead Time for Fruit Drying Machine - Three Layer Belt Dryer – Ligong, The product will supply to all over the world, such as: Comoros, Bulgaria, Lebanon, Our solutions have national accreditation requirements for qualified, good quality products, affordable value, was welcomed by individuals all over the world. Our products will continue to improve inside the order and appear forward to cooperation with you, Definitely should any of those goods be of curiosity to you, be sure to letus know. We'll be satisfied to supply you a quotation up on receipt of the detailed needs.

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!