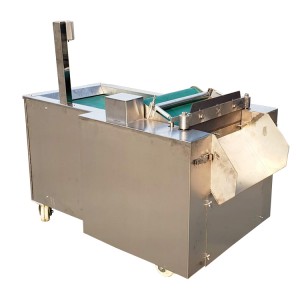

Lg-500 Reciprocating Vegetable Cutter

Main Parameters

1. Specification section 2-70; Slice more than 2mm, cut into 20×20, 30×30, 40×40 (to be determined when ordering)

2.output: 500-1000kg/h

3.supporting power: Y100L2-4 3KW

4.feed groove width: 500mm

5.overall size: 1350×900×1250mm

6.the machine weight: 210kg

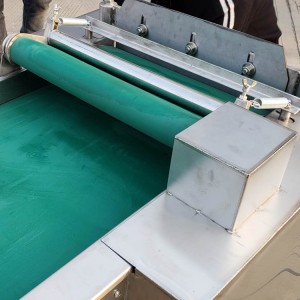

Working Principle

The material walks forward on the conveyor belt of the feeding trough, and after being clamped and pressed by the upper pressure belt, it is sent to the vertical knife that reciprocates up and down and is cut into segments. If the vertical knife is equipped with a group of equidistant small vertical knives, the material is cut into squares or rectangular blocks

Cut size

Cutting specifications can be changed by changing vertical knives (due to different distances of small vertical knives welded on different vertical knives, which should be explained when ordering) and changing the stepping distance of upper and lower conveyor belt.