Vibratory draining machine distributing machine

Description

I. Equipment Introduction

Vibration asphalt cloth machine is widely used in dehydrated vegetables, tea, dried fruit, spices, medicine, food and other industries, vibration using vibration motor excitation as vibration source, so that the material is thrown up on the screen plate, at the same time as a straight motion forward, materials from the feeder evenly into the feed port of the screen machine, Through the multi-layer screen to produce a number of specifications of the screen, under the screen, respectively from their respective outlet discharge. With low energy consumption, high output, simple structure, easy maintenance, no dust overflow, automatic discharge, more suitable for assembly line operation.

Vibration asphalt cloth machine is driven by vibration motor, when the vibration motor is synchronous, reverse rotation, the vibration force generated by the eccentric block in the direction of parallel to the axis of the motor offset each other, in the direction perpendicular to the motor shaft stacked as a resultant force, so the motion trajectory of the screen machine is a straight line. The motor shaft relative to the screen surface has a dip Angle, under the combined action of the vibration force and the material from gravity, the material on the screen surface was thrown up leaping forward linear motion, so as to achieve the purpose of screening and grading the material. It can be used to realize automatic operation in the assembly line. It has the characteristics of low energy consumption, high efficiency, simple structure, easy maintenance and fully enclosed structure without dust overflow and dispersion. Can be screened into mesh 100 mesh (dry material), can be screened out of different particle sizes of materials.

Vibrating bitumen distributor can also screen and classify powdery and granular materials, widely used in plastics, abrasives, chemical industry, medicine, building materials, food, carbon, chemical fertilizer and other industries.

1. Screen machine design, exquisite and easy to assemble, one person can operate the screen machine.

2. With a large screening area and high efficiency processing capacity.

3. Unique screen plate structure design, convenient and fast replacement screen (only 1 minute), in addition, this design allows the use of a variety of screen plate (acrylic plate, stainless steel punching plate, stainless steel wire mesh, etc.).

Ⅱ. Equipment Installation

1. The machine must be placed on a solid dry, ventilated level ground, and the ground must be calibrated with a level instrument to ensure that the machine works smoothly and reliably.

2. The voltage used by the machine is three-phase 220V/60Hz, and the power supply voltage is determined to be consistent with the voltage used by the machine; Power switch should be installed outside the body before entering the line.

3. The grounding wire is reliably grounded, and the power line is fastened and sealed with the inlet and outlet parts of the machine to avoid water leakage and electricity leakage.

4. There should be no impact vibration or abnormal sound when the machine is running empty. Otherwise, the machine will be stopped for inspection.

Ⅲ. Operation Steps

1. The operator should be familiar with the performance of the whole equipment and understand the function and operation method of each component of the unit.

2. Before starting the machine, we must carefully check the connection parts of mechanical and electrical equipment, bolts and so on should not be loose, whether there is a jam phenomenon, no abnormal sound, all normal before starting.

3. The machine can be fed after normal operation, uniform feeding, not steep and large amount of material can move forward evenly on the vibrating screen, reflecting that the equipment is normal.

Ⅳ. Notes

1. According to different types of materials, ensure uniform feeding.

2. Before production start, first no-load operation test, check the vibration plate operation, check whether the transmission part is normal.

3. Do not place any irrelevant items outside the vibration plate, so as not to boot accidents.

4. Once abnormal phenomenon is found during operation, the power supply should be cut off immediately (emergency stop button) and stop for inspection.

5. If the boot jitter is severe, check whether the fasteners are loose; Check whether the Angle of vibration motor swing plate (eccentric plate) is the same on both sides; Check the equipment and adjust the feet to ensure the equipment level.

Ⅴ. Maintenance and Maintenance

1. Check whether the vibration spring is intact and the bolts are fastened before starting the machine.

2. Every 3-6 months to check the motor bearing oil replacement once.

Vi. Production Line Configuration

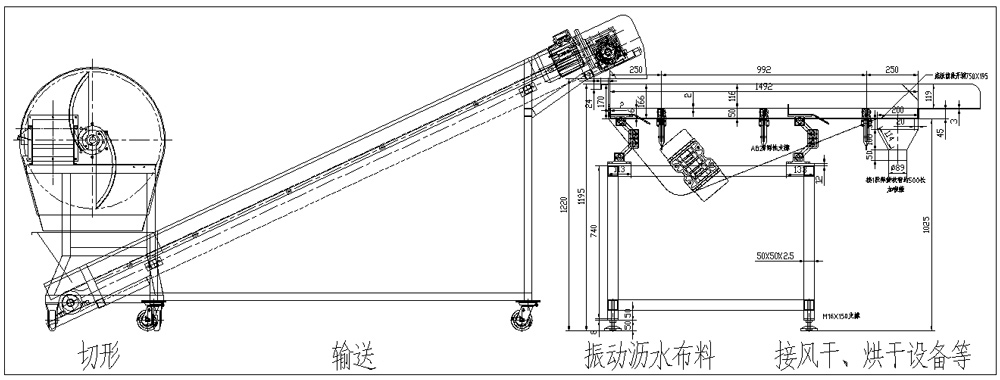

Vibration asphalt cloth machine in addition to the use alone, configuration to the automatic production line, common in the production line of dehydrated vegetables, the previous process for the material cutting shape, blanching, after the process for the material drying packaging or automatic drying.